We have standardization and professional service system

Ensure you enjoy the high quality and efficiency service.Product Description

Basic information of pipe:

| 1 | Type: | The T-type Joint Pipe (Push-on) |

| The K-type Joint Pipe | ||

| The Self-Restrained Joint Pipes | ||

| 2 | Standard: | ISO2531, EN545, EN598, GOST5525 |

| 3 | Size: | DN80~2600mm |

| 4 | Material: | Ductile Cast Iron |

| 5 | Pressure: | 50Bar- 10Bar |

| 6 | Wall Thickness Class: | K9, K8, C40/C30/C25 |

| 7 | Length: | 6m for bulk vessel and 5.7m for containers |

| 8 | Application: | Water supply project, drainage, sewage, irrigation, water pipeline |

| 9 | Certificate: | ISO9001, BV, WRAS, SGS |

| 10 | Internal Coating: | a). Portland cement mortar lining |

| b). Sulphate Resistant cement mortar lining | ||

| c). High-Aluminum cement mortar lining | ||

| d). Fusion bonded epoxy coating | ||

| e). Black bitumen painting or epoxy painting | ||

| f). other special requirement like PU Lining | ||

| 11 | External Coating: | a). zinc +bitumen painting |

| b). Fusion bonded epoxy coating | ||

| c). Zinc-aluminum alloy + liquid epoxy painting | ||

| d). other special requirement like PU coating | ||

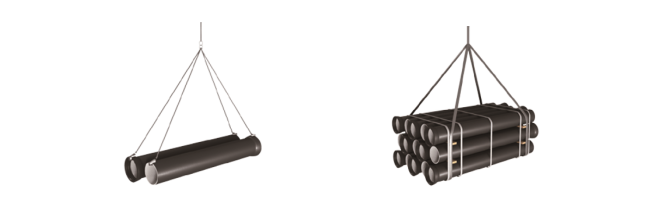

| 12 | Packing: | Bundles for small size≤DN300 ; in bulk for bigger size>DN300 |

Product Features

Storage and Transportation

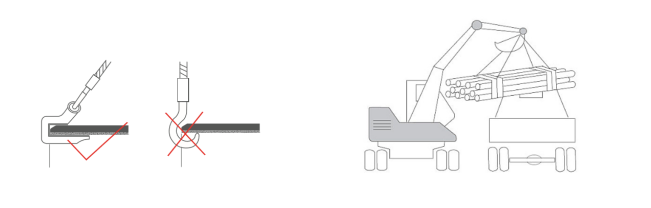

1. Lifting of Ductile Iron pipes

The crane or forklift is available for lifting, where special hooks shall be applied, as shown in Figure 1. The special hooks include steel hook covered by rubber, nylon strap or steel wire rope covered by rubber, so as not to damage the internal cement mortar lining and external protective coating, thus protecting coating of both sides.

If ductile iron pipes in loose (>DN300), special hook or lifting strap can be used to lift one or several ductile iron pipes each time, but if ductile iron pipes packed in bundles(≤DN300), strap and special lifting tools shall be used to lift them from the bottom of whole bundle. It is prohibited to directly hook pipes or package strap so as to avoid packing distortion, breakage of package straps or bundle-off during lifting as following. (≤DN300

2. Transportation of Ductile Iron pipes

If truck or train is adopted for transportation, the floor must be cleaned and two or more pieces of wood shall be placed on the carriage floor so as to avoid the direct contact between the socket end and carriage floor; At the same time, the loading scheme shall be prepared according to the acceptable capacity of vehicle;

If iron pipes are loaded in more than one layer, the pipe spigot and socket end of each layer shall be staggered and finally fixed with steel wire rope firmly; the soft protective materials shall be used to separate pipe from pipe, pipe and rigid vehicle body, as well as pipe and fastening steel ropes.

While unloading from the vehicle, it is necessary to avoid directly pulling or dropping the ductile iron pipe, over the ground, even over the sand ground.

3. Shipment:

Normally ductile iron pipes are shipped by container for smaller quantity or especial required by customs, or bulk vessel for bigger quantity. For container, pipes usually produced at 5.7m length, for bulk vessel at 6m length. But whatever by container or bulk vessel, some reinforce measures are necessary to avoid any damage during long shipping. The loading pictures are as following:

4. Storage of Ductile Iron pipes

The selected site for ductile iron pipe storage shall be flat and solid with a suitable approach road for vehicles. and Pipes should be stacked on a base of raised wooden battens to avoid their direct contact with the ground. The bottom layer of pipes should be securely anchored with wooden wedges.

Ductile iron pipes can be stacked in two patterns, the square and pyramidal form. But for each pattern, the socket and spigot end of pipe shall be arranged alternately as below pictures showing.

For further information, please contact us directly!

Copyright © Beijing Solaire International Corporation All Rights Reserved | Sitemap |