We have standardization and professional service system

Ensure you enjoy the high quality and efficiency service.Product Description

Polyethylene sleeving:

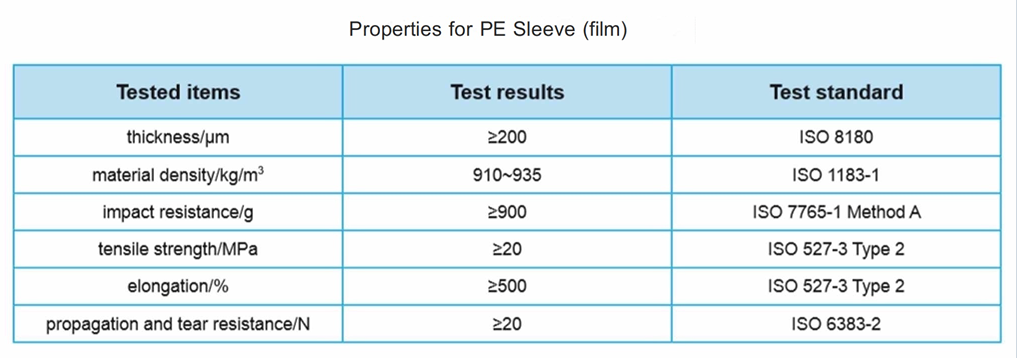

PE sleeving is the Polyethylene or a mixture of polyethylene and/or ethylene and olefin copolymers sleeve (film) with thickness of 0.2mm that is wrapped on external walls of the pipe on the construction site. It can prevent direct contact between cast iron pipes and the soil. Meanwhile, it also prevents underground moisture from corroding the pipelines. It is used to supplement the basic pipe coating (metalic Znic + HCPE finishing layer) in certain case of highly corrosive soils or in the presence of stray current.

The anti-corrosion mechanisms for PE sleeve (film) wrapped outside zinc coating are as following: First of all, PE sleeve can separate the pipelines from corrosive soil and inhibit the generation of electrochemical cell. At the same time, it can also isolate stray current. The PE sleeve is a kind of anti-corrosion method whose performance is achieved through the changing of corrosive environment: it can change the corrosive environment from non-homogeneous soil with strong aggressivity into one that is homogeneous with weak aggressivity.

Application fields:

It is suggested to adopt this kind of protective layer for corrosive soil, for example: Soil with low resistivity (with indicator of high aggressivity); Regions with stray current; Regions with high chlorine or sulphur content or active bacteria indicated by the analysis.

Polyethylene sleeving and Polyurethane coating have similar characters and property, both used in corrosive soils to protect the ductile iron pipe, but the Polyurethane coating is much more expensive than Polyethylene sleeving, so normally speaking, outside protection, Polyethylene sleeving is the best choose.

Copyright © Beijing Solaire International Corporation All Rights Reserved | Sitemap |