We have standardization and professional service system

Ensure you enjoy the high quality and efficiency service.A: Cement-mortar linings. Cement-mortar linings have been successfully used to protect the interior of iron pipe and fittings since 1922. Cement linings prevent tuberculation by creating a high pH at the pipe wall and ultimately by providing a physical barrier to the water.

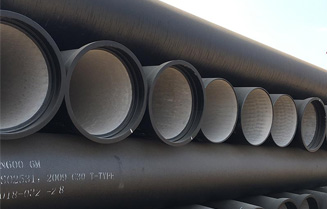

A: Yes. Cement-mortar-lined Ductile Iron Pipe can be used for certain wastewater applications. Ductile Iron pipe and fittings are normally furnished with a cement-mortar lining conforming to ANSI/AWWA C104/A21.4. While originally developed to prevent tuberculation in water mains, cement-mortar lining is also highly suitable for non-septic gravity sewers and sanitary sewer force mains. Long-term testing and experience of cement-mortar-lined iron pipe, both in the field and in the laboratory, have proven its effectiveness for these applications.

In addition to the uses mentioned above, cement-mortar-lined Ductile Iron Pipe can also be used for seawater applications. Special linings are often recommended for Ductile Iron Pipe used to transport septic sewage where hydrogen sulphides create a corrosion-related problem. Please contact the SOLAIRE PIPELINE regarding the most suitable lining for this condition or other special services.

A: Yes. The use of select, non-corrosive material (such as sand or limestone) for bedding and backfill is referred to as “trench improvement.” It is recognized that trench improvement generally provides good structural support and helps delay the onset of corrosion activity. However, experience has shown that trench improvement does not provide long-term protection to the pipe, particularly in highly aggressive soil environments. Permeation of native soil and moisture into the select backfill over time tends to make the select material take on corrosive properties. Therefore, trench improvement should not be used as the only method of corrosion control. Polyethylene encasement remains the most effective method for corrosion prevention of Ductile Iron Pipe.

A: Properly designed and installed Ductile Iron Pipe systems could easily have a life expectancy of more than 100 years. Unlike other pipe materials, the physical properties of Ductile Iron Pipe do not change with age. As long as Ductile Iron Pipe is not subjected to loadings and pressures in excess of its original capabilities, the only factor that could shorten its life is corrosion. Internal corrosion has been effectively eliminated with the evolution of cement-mortar linings and other special linings. Also, not all soil environments are considered corrosive to iron pipe.

A common procedure used to determine if the soil is aggressive to an iron pipe is the 10-point soil evaluation procedure outlined in Appendix A of the ANSI/AWWA C105/A21.5 Standard “Polyethylene Encasement for Ductile Iron Pipe Systems.” If the soil tests corrosive to Ductile Iron Pipe, then corrosion protection is warranted. Polyethylene encasement is the corrosion protection method normally recommended by the Ductile Iron Pipe Research Association and the manufacturers of Ductile Iron Pipe. If the soil is determined non-corrosive when tested in accordance with Appendix A of ANSI/AWWA C105/A21.5, or if it is determined corrosive and the pipe is encased with polyethylene in accordance with the standard, Ductile Iron Pipe could have a life expectancy of more than 100 years. If Ductile Iron Pipe is installed in aggressive environments without protection, its life expectancy would mainly be a function of that environment.

Copyright © Beijing Solaire International Corporation All Rights Reserved | Sitemap |